At a commercial enterprise production plant with a capacity of nearly 150 workers, people were coming and going, performing poorly, and frequently making mistakes, in no small part because of what appeared to be a lack of standardized operating procedures regarding most of the job functions, basic machine operation, and who to contact when something goes wrong.

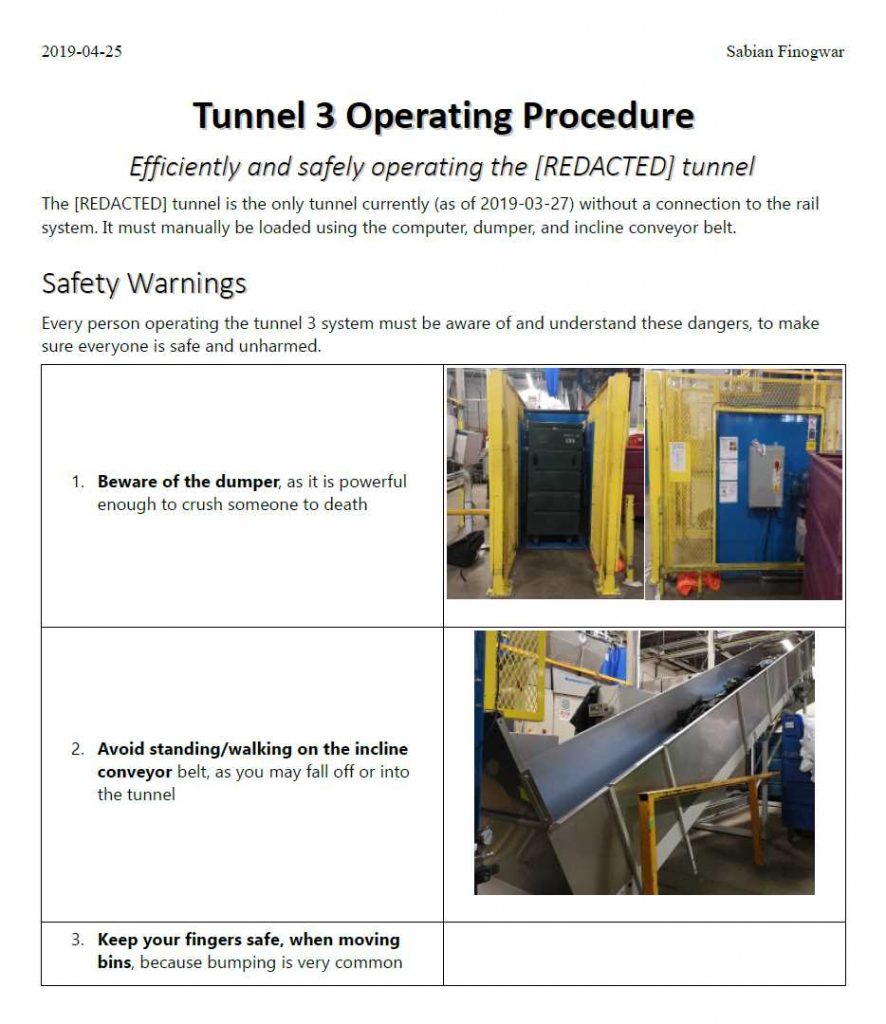

Clearly, this led to numerous problems within the plant, so several clearly labeled, detailed, and simply explained quick guides, and detailed machine operation manuals were made entirely from scratch, using purely the learned experience gained from working with the company, all photos were taken on site, and icons were cropped from photos or taken from the internet. The guides, procedures, and operating manuals were put together to uplift the company’s lacking training effectiveness and aid the development of training procedures for new hires and long-time workers to perform consistently, and have a tangible guide to check their understandings and troubleshoot problems on their own, and become more self-sustaining, in general.

LinenProcessing_2018-12-13_red RailOperationQuickGuide_2018-08-06_red Tunnel3Procedure_red DryerUnloadingGuide_2018-05-07_red MachineOperation_2019-02-28_red RailOperationGuide_2018-10-13_red FeederGuide_2018-11-11_red Customers_2019-03-28_Chronological_Condensed_red FallenLinenSignage_red